This piece started with a 3D printed figure made by my son David. I coated it with a thin layer of our new acrylic graphite paint, applied directly to the plastic without a sealer underneath. It was electroformed with copper and then plated with nickel silver to finish.

Stir the graphite paint and then apply a thin later of paint over the plastic. I use a stiff brush to "scrub" the paint into crevices with a dry brush technique to retain details. This paint has an acrylic stabilizer to keep it from flaking or rinsing off in solution. Let the paint dry throughly. I use a blow dryer to speed things up. Check for any missing spots and touch up as needed. Note: If you are using the paint on an organic object you will want to seal it first.

Attach a copper wire prior to electroforming. This piece was started on a current level of about .60 I moved the wire after about an hour of plating and then a few more times to keep it from sticking. As I pulled the piece to move the wire I noticed a few places that needed to be touched up. The piece was rinsed with distilled water and I applied paint in a few spots where the plating was missing. After drying I wrapped the wire around the piece and returned to the plating bath. I reduced the current to .45 and electroformed for about 8-10 hours.

Here is the piece after copper electroforming.

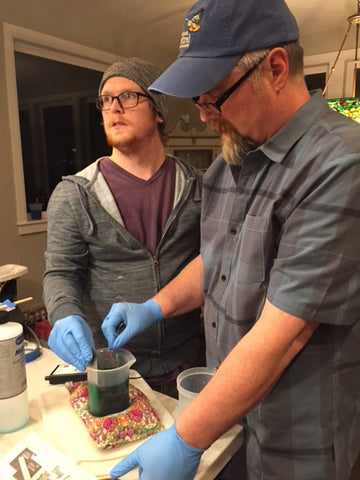

Here's where I step aside and let these two crazy guys take over. David is my son and Dan is my husband (otherwise known as the engineer who created all of the technology and techniques for our products). The piece is being electro-cleaned with Rio Grande Electro-Clean solution. They used a stainless steel anode and we heated the solution by placing it on a rice bag that was heated for a few minutes in the microwave. We never do anything very sophisticated but there are fancier methods for heating plating solutions. This process only takes a few minutes.

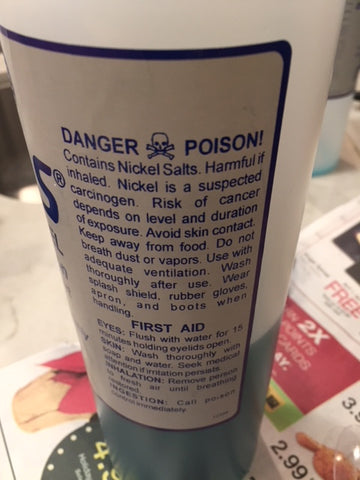

Be sure and follow safety precautions as directed on products like Nickel plating solution.

After electro-cleaning, Dan and David plated the piece with Bright Nickel (Midas Bright Nickel from Rio Grande). They used a nickel anode and it took about 5 minutes to fully plate. As you can see the piece has a lot of deep crevices and so the plating takes longer than an simple shape would.

Here is the nickel plated piece! David added red glass rhinestone eyes to finish the piece and added a chain to gift this to his lovely wife for Christmas.

Hello, the whole thing is going perfectly here, that’s truly good, keep up writing.

ReplyDelete